What Are You Looking For?

What Are You Looking For?

Product description:

AZ150 Galvalume is a hot-dip aluminium-zinc alloy coating steel. The resulting coating has excellent corrosion resistance and can be used in harsh environments. This combination results in a durable and corrosion-resistant material that can be used in any application with high strength or hardness.

AZ150 galvalume is a high-quality, corrosion-resistant alloy commonly used in the construction and transportation industries. It’s highly resistant to rust, oxidation, and corrosion, making it an excellent choice for those who need to ship items or have them exposed to weather conditions.

Product description:

AZ150 means that in the triple spot test in the en 10346 standard, the minimum total coating mass on both surfaces of the aluminum-zinc alloy coating is 150g per square meter. Equivalent to Total Both Sides in ASTM a792 standard is 0.50 oz/square foot.

This steel’s coating alloy is made up of 55% aluminium, 43.4% zinc, and 1.6% silica. The coating of this steel serves as general corrosion’s passivating barrier. The other coating layer allows the formation of galvanic element once the sheet is exposed to electrolyte or moisture. This exposure results in the flowing over of zinc ions and corrosion protection of exposed steel. It also helps protect the steel’s trimmed edges and scratches.

Application:

Building roofs, walls, electrical cabinets, home appliances, automobiles, color coating substrates, etc.

Product specification:

| Standard |

JIS / EN / ASTM Standard |

|

Grades |

SGLCC / SGL400 / SGL440 / SGL570 / SGLCD |

|

ASTM A792M CS-A / CS-B / CS-C |

|

|

SS230 / SS255 / SS275 / SS340 / SS550 |

|

|

DX51D / DX52D / DX53D |

|

|

S220GD / S250GD / S280GD / S320GD / S350GD / S550GD |

|

|

Coating |

AZ40-AZ150 |

|

Spangle |

Regular Spangle |

|

Sizes |

Thickness: 0.23mm - 3.0mm Width: 900mm-1250mm,or customer's requirement |

|

Surface treatment |

Chromate Treatment, Anti-fingerprint |

Chemical composition:

|

Al |

Zn |

Si |

Fe |

Cu |

Cd |

Pb |

Sn |

Ni |

Ti +Ba+Cr |

|

55-58 |

41-43 |

1.5-2 |

0.25 |

0.03 |

0.05 |

0.01 |

0.05 |

0.05 |

0.05 |

Mechanical property:

|

Grade |

Yield Strength MPa≥ |

Tensile Strength MPa≥ |

Elongation A%≥ |

|

DX51D+Z/ZM/AZ/AM |

240-380 |

270-500 |

22 |

|

DX52D+Z/ZM/AZ/AM |

140-300 |

270-420 |

26 |

|

DX53D+Z/ZM/AZ/AM |

140-260 |

270-380 |

30 |

|

DX54D+Z/ZM/AZ/AM |

120-220 |

260-350 |

36 |

|

S220GD+Z/ZM/AM |

220 |

300 |

20 |

|

S250GD+Z/ZM/AZ/AM |

250 |

330 |

19 |

|

S280GD+Z/ZM/AM |

280 |

360 |

18 |

|

S300GD+AZ/AM |

300 |

380 |

18 |

|

S320GD+Z/ZM/AM |

320 |

390 |

17 |

|

S350GD+Z/ZM/AZ/AM |

350 |

420 |

16 |

|

S450GD+AZ/AM |

450 |

480 |

15 |

|

S550GD+Z/ZM/AZ/AM |

550 |

550 |

- |

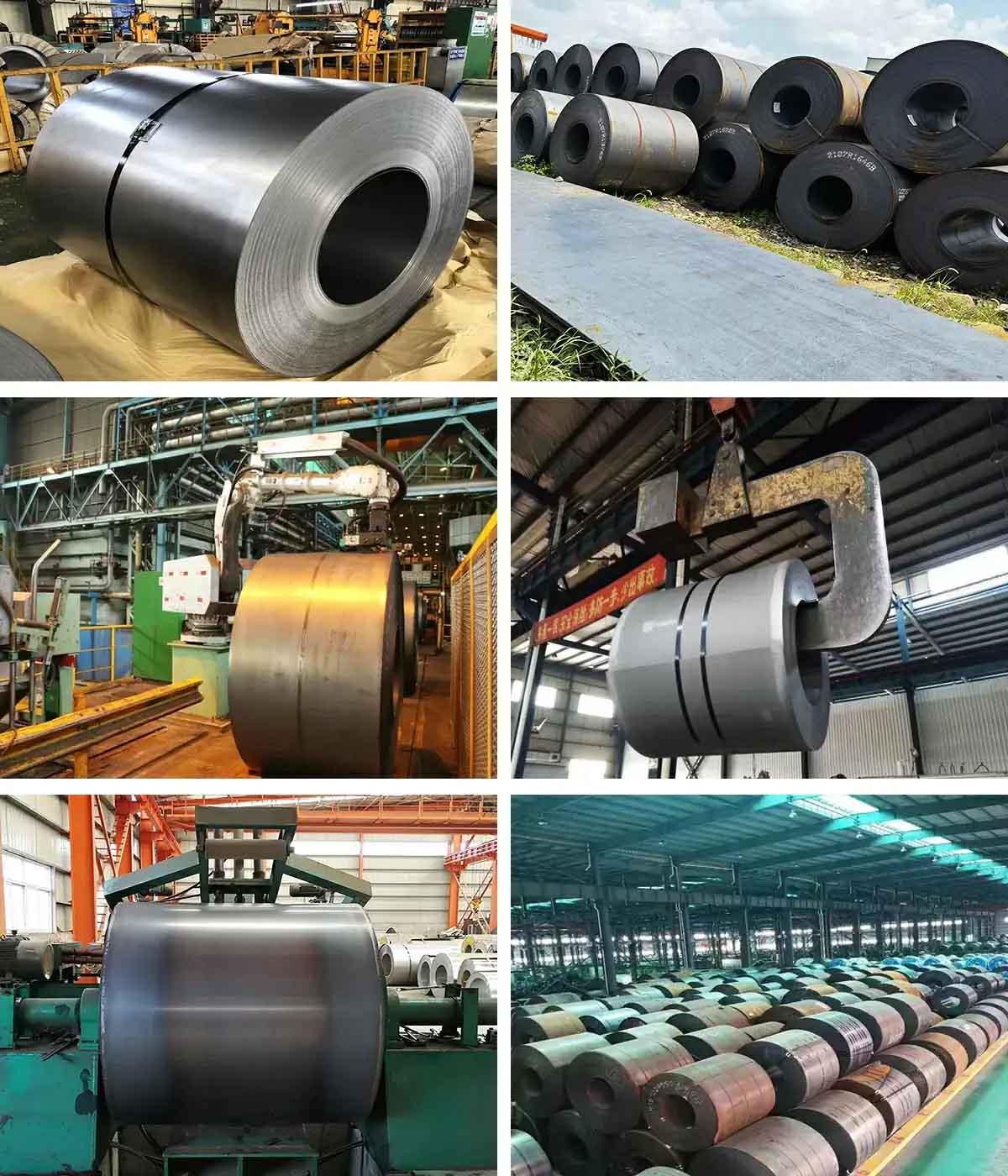

Products Show

Factory Show

Quality inspection process

FAQ:

Q1:Can you send samples?

A:Of course, we can provide customers with free samples.

Q2:What product information do I need to provide?

A:Please kindly provide the grade, width, thickness, surface treatment requirement should you have and quantities you need to purchase.

Q3:It's my first time to import steel products, can you help me with it?

A:Sure,we have agent to arrange the shipment, we will do it together with you.

Q4:What ports of shipment are there?

A:Under normal circumstances, we ship from Shanghai, Tianjin, Qingdao, Ningbo ports, you can specify other ports according to your needs.

Q5:Can you accept customize?

A: Yes. It can be customized as per the customers' request.

Q6:What are the certifications for your products?

A:We have ISO 9001, MTC, ISO14001,third parties’ inspections are all available such SGS, BV ect.

Q7:How long does your delivery time take?

A:In general, our delivery time is within 7-15 days, and may be longer if the quantity is extremely large or special circumstances occur.

Q8: How many countries you already exported to?

A:We have exported to Canada, Russia, Belarus, Poland, Brazil, Mexico, Colombia, Ecuador, Peru, Iran, Vietnam, Malaysia, UAE, Nigeria and other countries. Our export experience is rich, we are familiar with different market needs, can help customers avoid a lot of trouble.

Q9:Can I go to your factory to visit?

A:Of course, we welcome customers from all over the world to visit our factory.

Q10:Does the product have quality inspection before loading?

A:Of course, all our products are strictly tested for quality before packaging, and unqualified products will be destroyed and customers can appoint third parties to inspect the products before loading too.

Q11:How to pack the products?

A: Standard export sea-worthy packaging, the inner layer has a waterproof paper outer layer with iron packaging and is fixed with a fumigation wooden pallet.It can effectively protect products from corrosion and various climate changes during ocean transportation.

Tags :

Questions? Start The Conversation