What Are You Looking For?

What Are You Looking For?

Product description:

PPGI coil is a popular material that is based on hot-dip galvanized steel or electrogalvanized steel (galvanized layer) coated with multiple layers of organic coating to prevent it from rusting. Used for roof panels, wall panels, furniture, household appliances, auto parts and so on. It maintains the strength of galvanized steel while its organic coating provides a variety of colors and an attractive appearance.

Product description:

Hot-dip galvanized PPGI steel:

The main use of hot-dip galvanized steel plate as the substrate, due to the protection of zinc layer and organic coating, its service life is longer than the hot-dip galvanized plate. The available zinc layer is 275 g/m2.

Electrogalvanized PPGI steel:

Electrogalvanized sheet is used as the base material. Because the zinc layer of electrogalvanized sheet is thinner, usually 20g/㎡, its corrosion resistance is not as good as that of hot galvanized sheet. Therefore, this product is not suitable for outdoor walls and roofs. However, it has a beautiful appearance and excellent processing properties, mainly used in household appliances, steel furniture, interior decoration and so on.

PPGI color coating roll advantages:

Color coated galvanized coil has a variety of colors and patterns to meet different styles and uses. The colorful coating also makes PPGI steel more corrosion resistant and durable. PPGI steel coil has excellent processing properties. So you can make the coil into different products according to your needs. Color-coated galvanized steel coils also retain the strength of steel, making them tough and safe. PPGI coated coils are lightweight and easy to transport and install. More affordable compared to PPGL steel.

Surface treatment:

Tectorial membrane:

The process is to coat the steel coil with a transparent organic film (30-50 nm) at high temperatures. It has some unique properties, such as fire resistance, fingerprint resistance, excellent durability, anti-fouling ability and so on. Obviously, this treatment method can protect the steel coil well during storage and transportation.

knurling:

Embossed PPGI coil designs are available in different patterns. Popular patterns are stucco, diamond, etc. And it's customizable. Compared to smooth steel coils, it has a vivid 3D effect.

Coating type:

In the steel coil coating, the durability is the role of resin and pigment, the most commonly used topcoats are polyester, silicon modified polyester, high-durability polyester and polyvinylidene fluoride.

1.Polyester PE:

Good adhesion, rich color, wide range in formability and outdoor durability, medium chemical resistance, low cost.

2.Silicon modified polyester SMP:

The hardness, wear resistance and heat resistance of the film are good. And good external durability and resistance to pulverization, gloss retention, general flexibility, medium cost.

3.High durability Polyester HDP:

Excellent color retention and UV resistance, excellent outdoor durability and powder resistance, good film adhesion, rich color, excellent cost performance.

4.Polyvinylidene fluoride PVDF:

Excellent color retention and UV resistance, excellent outdoor durability and powder resistance, excellent solvent resistance, good formability, dirt resistance, limited color, high cost.

Application:

Construction industry: such as roof, interior and exterior wall panels, balcony panels, ceiling, partition wall, Windows, door panels, etc.

Transportation: such as decorative panels for cars, decks for trains or ships, containers, etc.

Electrical equipment: mainly used to make refrigerators, washing machines, air conditioners and other shells. PPGI coils for household appliances have the best quality and the highest production requirements.

Furniture: such as wardrobes, lockers, radiators, lampshades, tables, beds, bookcases, shelves, etc.

Other industries: such as rolling curtains, billboards, traffic signs, elevators, whiteboards, ETC.

Product specification:

|

Product |

Color Coated Coil |

|

Length |

as required |

|

Width |

600-1500mm or as customer's requirements |

|

Thickness |

0.2-6mm or as required |

|

Standard |

AISI,ASTM,DIN,JIS,GB,JIS,SUS,EN,etc. |

|

Surface Treatment |

Clean, blasting and painting according to customer requirement |

|

Material |

DX51D Z/AZ, DX52D Z/AZ, DX53D Z/AZ, DX54D Z/AZ, DX56D Z/AZ,Q195A-Q235A, S280GD, S350GD, SGCC etc |

|

Spangle |

Regular spangle, minimal spangle, zero spangle, big spangle |

|

Application |

Construction industry, shipbuilding industry, vehicle manufacturing industry, furniture industry, electrical industry, etc. |

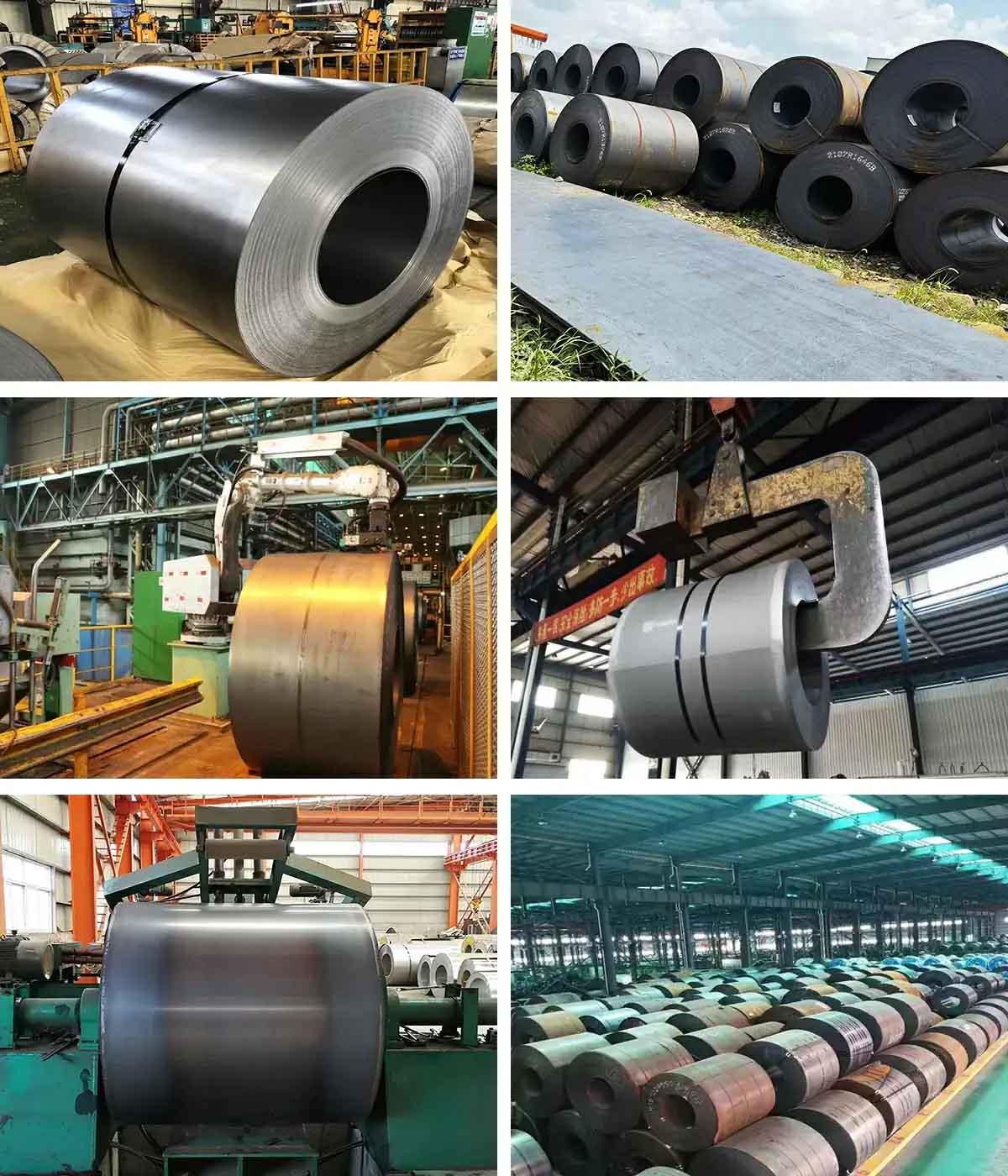

Products Show

Factory Show

Quality inspection process

FAQ:

Q1:Can you send samples?

A:Of course, we can provide customers with free samples.

Q2:What product information do I need to provide?

A:Please kindly provide the grade, width, thickness, surface treatment requirement should you have and quantities you need to purchase.

Q3:It's my first time to import steel products, can you help me with it?

A:Sure,we have agent to arrange the shipment, we will do it together with you.

Q4:What ports of shipment are there?

A:Under normal circumstances, we ship from Shanghai, Tianjin, Qingdao, Ningbo ports, you can specify other ports according to your needs.

Q5:Can you accept customize?

A: Yes. It can be customized as per the customers' request.

Q6:What are the certifications for your products?

A:We have ISO 9001, MTC, ISO14001,third parties’ inspections are all available such SGS, BV ect.

Q7:How long does your delivery time take?

A:In general, our delivery time is within 7-15 days, and may be longer if the quantity is extremely large or special circumstances occur.

Q8: How many countries you already exported to?

A:We have exported to Canada, Russia, Belarus, Poland, Brazil, Mexico, Colombia, Ecuador, Peru, Iran, Vietnam, Malaysia, UAE, Nigeria and other countries. Our export experience is rich, we are familiar with different market needs, can help customers avoid a lot of trouble.

Q9:Can I go to your factory to visit?

A:Of course, we welcome customers from all over the world to visit our factory.

Q10:Does the product have quality inspection before loading?

A:Of course, all our products are strictly tested for quality before packaging, and unqualified products will be destroyed and customers can appoint third parties to inspect the products before loading too.

Q11:How to pack the products?

A: Standard export sea-worthy packaging, the inner layer has a waterproof paper outer layer with iron packaging and is fixed with a fumigation wooden pallet.It can effectively protect products from corrosion and various climate changes during ocean transportation.

Tags :

Questions? Start The Conversation