What Are You Looking For?

What Are You Looking For?

Product description:

ZM Zinc Aluminum Magnesium DX53D Hot Dip Galvanized Sheet Plate 6.0mm is a type of galvanized sheet plate with specific properties.

The ZM Zinc Aluminum Magnesium DX53D Hot Dip Galvanized Sheet Plate 6.0mm features a thickness of 6.0mm. It is manufactured using the hot dip galvanizing process, which provides excellent corrosion resistance.

Product description:

The addition of zinc, aluminum, and magnesium gives this sheet plate enhanced durability and protection against rust and corrosion. The DX53D grade indicates specific mechanical properties and performance characteristics.

This type of galvanized sheet plate is commonly used in a variety of applications, including construction, roofing, automotive, and manufacturing. It offers a reliable and long-lasting solution for those seeking corrosion-resistant and sturdy sheet plate.

The 6.0mm thickness provides added strength and rigidity, making it suitable for applications that require durability and structural integrity.

Whether used in structural components, exterior cladding, or other demanding applications, the ZM Zinc Aluminum Magnesium DX53D Hot Dip Galvanized Sheet Plate 6.0mm offers reliable performance and protection.

DC51D+Zm Zinc Aluminum Magnesium Hot Dipped Steel sheet/plate

Zinc-aluminum-magnesium(ZAM) coating is through the role of aluminum and magnesium, so that the hot dip coating has excellent corrosion resistance, wear resistance and processing, can be widely used in various fields. Zinc-aluminium-magnesium coated steel plate can be directly replaced by zinc-aluminium-magnesium coated steel plate without changing the existing processing, assembly, coating and other processes.

Most important, our steel sheet service capabilities include slitting,cutting to length, blanking, degreasing and brushing, stretcher leveling and metallurgical support.

DC51D+Zm Zinc Aluminum Magnesium Hot Dipped Steel sheet/plate

Zinc-aluminum-magnesium(ZAM) coating is through the role of aluminum and magnesium, so that the hot dip coating has excellent corrosion resistance, wear resistance and processing, can be widely used in various fields. Zinc-aluminium-magnesium coated steel plate can be directly replaced by zinc-aluminium-magnesium coated steel plate without changing the existing processing, assembly, coating and other processes.

Most important, our steel sheet service capabilities include slitting,cutting to length, blanking, degreasing and brushing, stretcher leveling and metallurgical support.

Advantages of ZAM coating:

● Longer service life than other coated products.

● Cut edge rust protection - the hallmark feature of ZAM.

● Thinner coating yet more protection - ecologically friendly.

● Excellent in severe environments - especially coastal and agricultural.

● Eliminates the need for post dip (batch) galvanizing.

● Superior formability due to coating characteristics Cost savings through longer service life and reduced maintenance.

● Bridges the product gap between heavily coated galvanized and costly stainless steel.

Application:

The applications of ZM Zinc Aluminum Magnesium DX53D Hot Dip Galvanized Sheet Plate 6.0mm can include the following:

1.Construction: It is used in the construction industry for roofing, siding, wall panels, and structural components, providing corrosion resistance and durability.

2.Automotive: This sheet plate can be utilized in the automotive sector for body panels, undercarriages, and components that require rust protection.

3.Manufacturing: It finds applications in manufacturing processes such as the production of appliances, furniture, and storage containers.

4.Sheet metal work: The galvanized sheet plate is suitable for sheet metal fabrication, including ductwork, ventilation systems, and enclosures.

5.Agricultural equipment: It is used in the manufacturing of agricultural machinery and equipment, as it offers resistance to harsh environmental conditions.

6.Industrial structures: The sheet plate can be employed in the construction of industrial buildings, warehouses, and storage facilities.

7.Decorative applications: With its zinc-aluminum-magnesium coating, it can be used in decorative elements, such as architectural facades and interior design.

8.Signage and billboards: The sheet plate may be used for creating signs and billboards due to its corrosion resistance and durability.

The specific application depends on the requirements and needs of the project. The combination of zinc, aluminum, and magnesium in the hot dip galvanizing process enhances the corrosion resistance and durability of the sheet plate, making it suitable for a wide range of applications.

Product specification:

|

Thickness(mm) |

0.3-2.0 |

|

Width(mm) |

750-1320 |

|

Metal Plating |

AZM60-AZM275 |

|

Steel coil weight (tons) |

5-8 |

|

Strength |

G250/G280/G300/G320/G345/G350/G550/DX51D/DX52D/DX53D |

Mechanical property:

|

Product Name |

Brand |

Yield Strength/Mpa |

Tensile Strength/Mpa |

Elongation after break/% |

|

Low carbon steel |

DX51D+AZM/ZM |

≤360 |

≤440 |

≥20 |

|

DX52D+AZM/ZM |

≤260 |

300-360 |

≥28 |

|

|

Interstitial atomic steel |

DX53D+AZM/ZM |

≤200 |

270-320 |

≥38 |

|

DX54D+AZM/ZM |

≤180 |

270-310 |

≥40 |

|

|

Structural Steel |

S250GD+AZM/ZM |

≥250 |

≥330 |

≥19 |

|

S350GD+AZM/ZM |

≥350 |

≥420 |

≥16 |

|

|

S450GD+AZM/ZM |

≥450 |

≥510 |

≥14 |

|

|

S550GD+AZM/ZM |

≥550 |

≥560 |

/ |

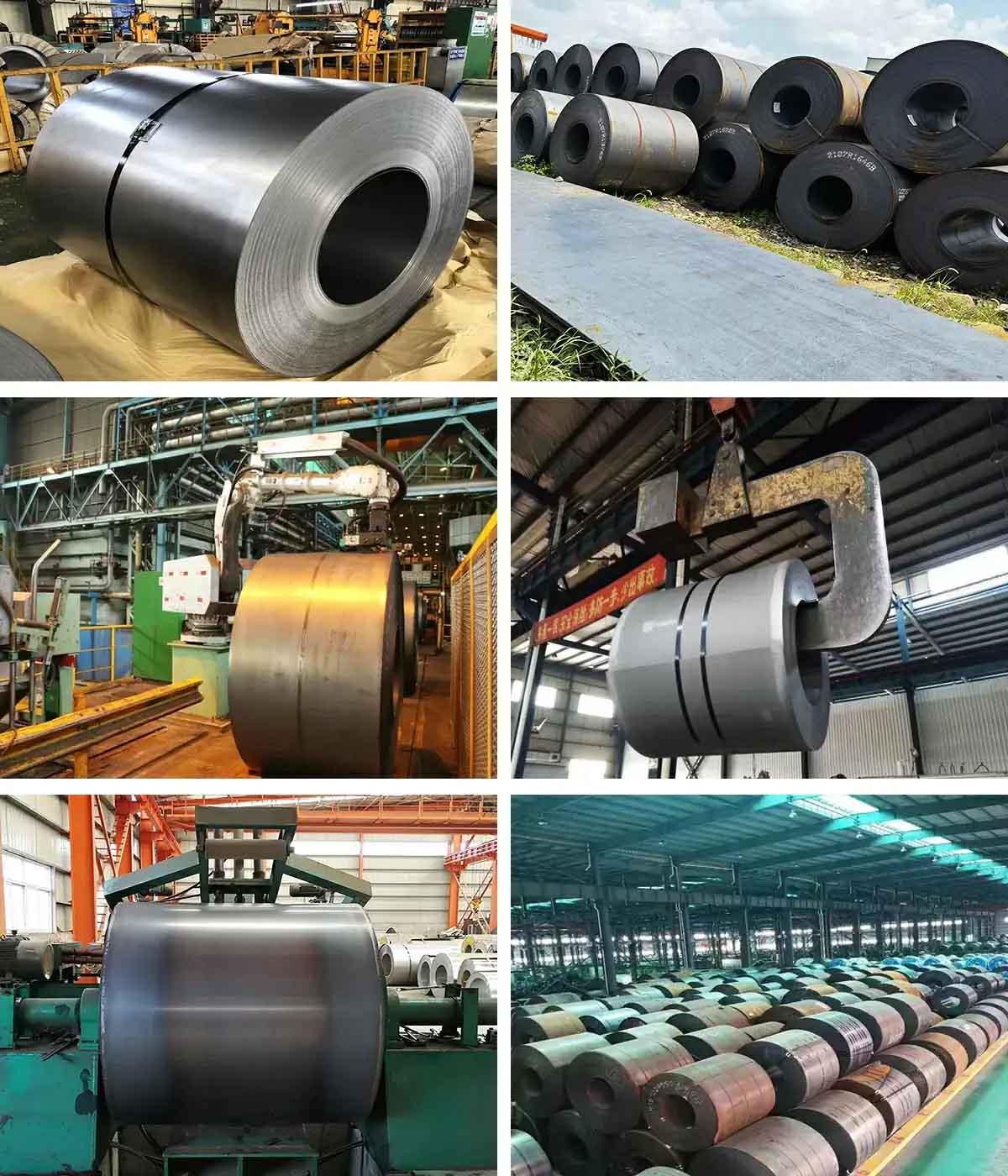

Products Show

Factory Show

Quality inspection process

FAQ:

Q1:Can you send samples?

A:Of course, we can provide customers with free samples.

Q2:What product information do I need to provide?

A:Please kindly provide the grade, width, thickness, surface treatment requirement should you have and quantities you need to purchase.

Q3:It's my first time to import steel products, can you help me with it?

A:Sure,we have agent to arrange the shipment, we will do it together with you.

Q4:What ports of shipment are there?

A:Under normal circumstances, we ship from Shanghai, Tianjin, Qingdao, Ningbo ports, you can specify other ports according to your needs.

Q5:Can you accept customize?

A: Yes. It can be customized as per the customers' request.

Q6:What are the certifications for your products?

A:We have ISO 9001, MTC, ISO14001,third parties’ inspections are all available such SGS, BV ect.

Q7:How long does your delivery time take?

A:In general, our delivery time is within 7-15 days, and may be longer if the quantity is extremely large or special circumstances occur.

Q8: How many countries you already exported to?

A:We have exported to Canada, Russia, Belarus, Poland, Brazil, Mexico, Colombia, Ecuador, Peru, Iran, Vietnam, Malaysia, UAE, Nigeria and other countries. Our export experience is rich, we are familiar with different market needs, can help customers avoid a lot of trouble.

Q9:Can I go to your factory to visit?

A:Of course, we welcome customers from all over the world to visit our factory.

Q10:Does the product have quality inspection before loading?

A:Of course, all our products are strictly tested for quality before packaging, and unqualified products will be destroyed and customers can appoint third parties to inspect the products before loading too.

Q11:How to pack the products?

A: Standard export sea-worthy packaging, the inner layer has a waterproof paper outer layer with iron packaging and is fixed with a fumigation wooden pallet.It can effectively protect products from corrosion and various climate changes during ocean transportation.

Tags :

Questions? Start The Conversation